Lâmina de Corte Ideal para Bordas de Bancadas

Visão Geral do Produto

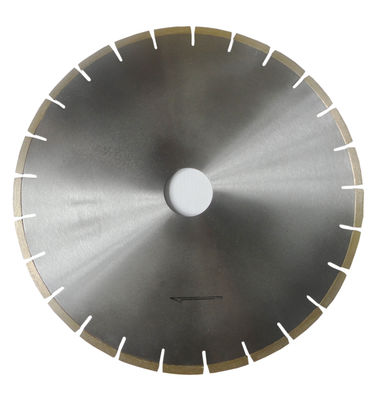

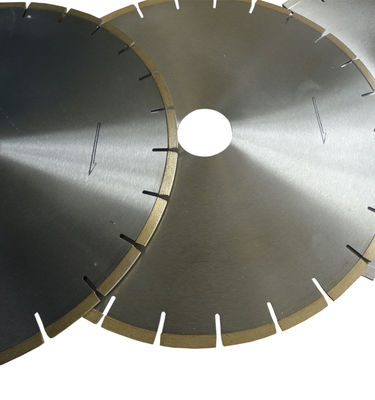

Alcance a perfeição na fabricação de bancadas com nossa Lâmina de Corte Ideal para Bordas de Bancadas, projetada especificamente para qualidade superior de corte de bordas em trabalhos de corte de bancadas de granito e mármore. Projetadas para fabricantes de pedra profissionais, estas lâminas de diamante avançadas oferecem nitidez de corte e eficiência de corte excepcionais, garantindo resultados sem lascas em ambos os lados do corte.

Especificações Técnicas

| Nome do Produto |

Diâmetro (mm) |

SteelCore (mm) |

Dimensão do Segmento (mm) |

Número de Segmentos |

Aplicação |

| Lâmina de Corte de Borda |

300 |

2.2 |

43/41*2.8*10 |

22 |

Granito, Quartzo, Mármore |

|

350 |

2.2 |

43/41*3.2*10 |

25 |

|

400 |

2.4 |

43/41*3.6*10 |

29 |

Principais Características e Benefícios

1. Qualidade Ideal de Corte de Borda em Trabalhos de Corte de Bancadas de Granito e Mármore

- Segmentos Projetados com Precisão: Otimizados para perfilamento e corte de bordas de bancadas

- Qualidade de Grau Profissional: Atende aos padrões da indústria para fabricação de bancadas de alta qualidade

2. Melhor Nitidez de Corte e Eficiência de Corte, Sem Lascas em Ambos os Lados

- Grão de Diamante Premium: Partículas de diamante de alta qualidade para cortes rápidos e limpos

- Matriz de Ligação Avançada: Especialmente formulada para as características do granito e mármore

- Tecnologia Anti-Lascas: Design especial da borda evita lascas na entrada e saída

- Proteção Dupla Face: Garante cortes limpos em ambas as superfícies superior e inferior

Lâminas Universais para Bancadas

- Matriz de Ligação Média: Adequada para todos os tipos de pedra

- Aplicação Versátil: Granito, mármore, quartzo, pedra industrializada

- Custo-Benefício: Uma lâmina para múltiplos materiais

Serviço Pós-Venda

- Suporte Técnico: Assistência online 24 horas por dia, 7 dias por semana

- Consultoria de Aplicação: Seleção ideal da lâmina

- Treinamento de Uso: Tutoriais em vídeo e documentação

- Solução de Problemas: Suporte especializado para solução de problemas

Perguntas Frequentes

P: O que torna essas lâminas ideais especificamente para trabalhos em bancadas?

R: Nossas lâminas apresentam perfis ultrafinos e formulações de ligação especializadas, projetadas especificamente para a precisão exigida na fabricação de bancadas, garantindo bordas sem lascas e mínimo desperdício de material.

P: Essas lâminas podem lidar com granito e mármore de forma eficaz?

R: Sim, oferecemos formulações específicas para cada material - ligação dura para granito e ligação macia para mármore, além de opções universais que funcionam excelentemente em ambos os tipos de pedra.

P: Como evito lascas ao cortar as bordas da bancada?

R: Use a velocidade correta da lâmina, garanta o alinhamento adequado da lâmina, corte do lado acabado, se possível, mantenha uma taxa de avanço constante e use nosso design de lâmina anti-lascas.

P: Qual a diferença entre as séries padrão e premium?

R: A série premium oferece 30% mais vida útil, velocidade de corte mais rápida e qualidade de borda superior. Elas são ideais para oficinas de fabricação de alto volume e projetos de bancadas premium.

P: Devo usar água ao cortar as bordas da bancada?

R: O corte úmido é recomendado para obter os melhores resultados - ele prolonga a vida útil da lâmina, reduz a poeira, evita o superaquecimento e proporciona os cortes mais limpos, especialmente importante para bordas visíveis.

Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!  Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!